- Brescia, Via fratelli Ugoni, 32 - 25126 Italy

- +39 030 25 59 291

- info@avogadroenergy.com

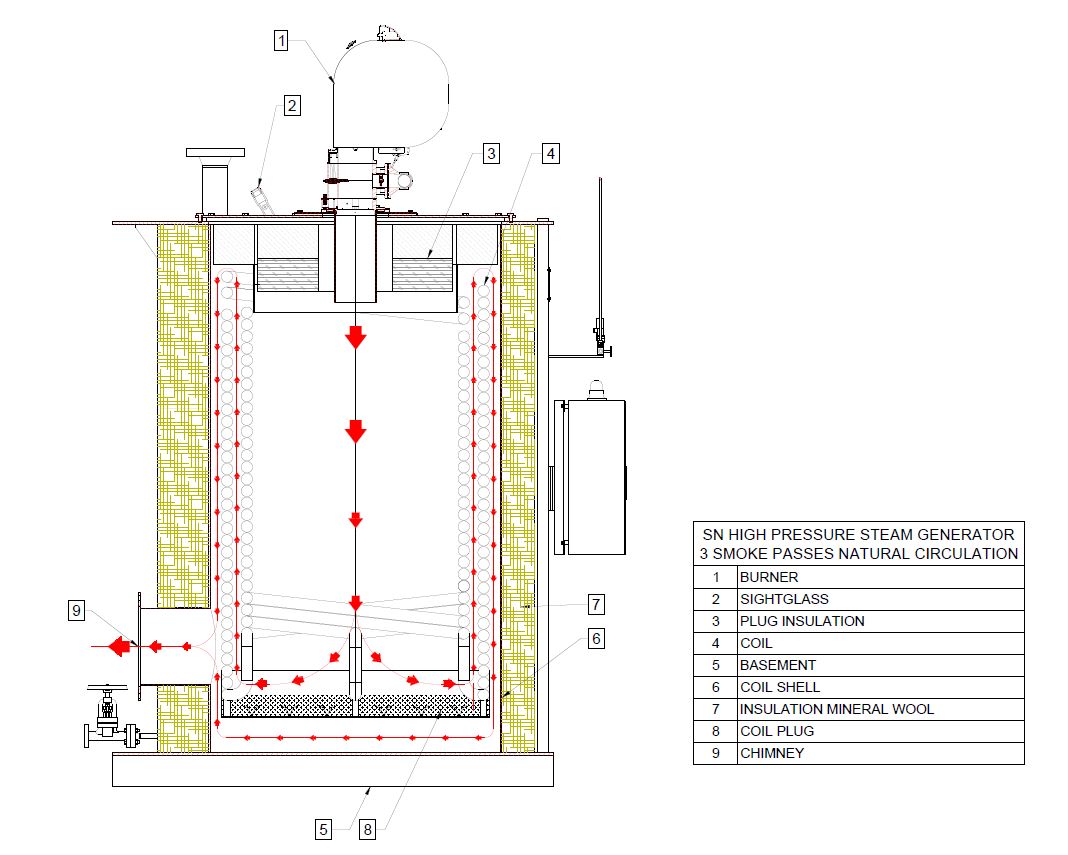

SN - Natural Circulation Steam Generator

High-pressure natural circulation steam generator

SN - Natural Circulation Steam Generator

Many technological processes, especially in the food industry, require heat production systems capable of reaching high temperatures (up to 250°C or more). The SN steam generator represents the ideal solution.

These generators, powered by gas or liquid fuel, operate without a condensate drain, water treatment, or circulation pump. They are easy to install and do not require collectors or special connections. The AR version includes a flue gas/air heat exchanger that preheats the combustion air using the residual heat from the flue gases, improving the efficiency of the equipment.

The SN is a high-pressure natural circulation steam generator designed to operate within a closed steam and condensate system. This configuration allows for exceptional energy efficiency, minimizing losses throughout the operational cycle. Thanks to the absence of blowdowns, no need for softened make-up water, and continuous chemical dosing, the SN stands out as the most economical and eco-friendly solution for steam generation.

In its most basic configuration, the boiler is used with a single user: the steam produced condenses on the thermal exchange surface of the user, generating condensate that returns by gravity to the generator to be transformed back into steam. This system ensures low consumption and optimal space management.

The SN has been designed to meet the needs of a wide range of industries, effectively supporting batch, continuous, or semi-continuous processes.