- Brescia, Via fratelli Ugoni, 32 - 25126 Italy

- +39 030 25 59 291

- info@avogadroenergy.com

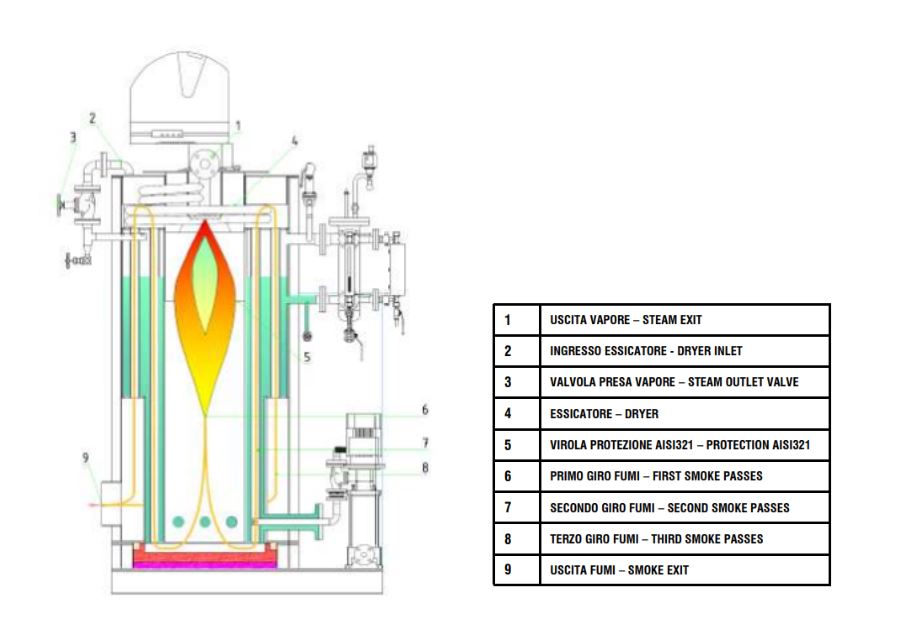

SVT - Rapid Steam Generator with Boiler Operator Exemption

Relevant Exemptions Under D.Lgs n. 93/2000 - Art. 2, Exclusions (Point F)

SVT - Rapid Steam Generator with Boiler Operator Exemption

The SVT steam generators are designed to comply with the Italian Legislative Decree 93/2000, which exempts certain steam boilers from the need for continuous monitoring by a qualified boiler operator (licensed fireman). These units do not require specific start-up procedures, making them ideal for applications where efficiency and simplicity are essential.

Relevant Exemptions Under D.Lgs n. 93/2000 - Art. 2, Exclusions (Point F):

This decree does not apply to the following devices, except for those indicated in Article 1, letter c):

- Pressure devices used for quick coffee preparation

- Domestic pressure cookers

- Generators, containers, and piping with a maximum allowable pressure not exceeding 0.5 bar

- Fixed fire extinguishers with a maximum allowable pressure not exceeding 10 bar or internal diameter smaller than 400 mm; portable extinguishers with gas cartridges at or below 18 bar

- Steam generators for water or superheated water with a total volume up to 25 liters and a maximum pressure of 32 bar

- Steam generators for water or superheated water where the product of the maximum allowable pressure in bar multiplied by the capacity in liters does not exceed 300, and the maximum allowable pressure is 10 bar.